Industrial automation has outpaced the tools used to maintain it. Across parcel hubs, airport baggage systems, and high‑volume manufacturing, equipment now runs faster, harder, and closer to its mechanical limits. Traditional monitoring tools see symptoms, not causes — and almost never at the speed required to prevent failures.

TinMan Systems closes that gap with real‑time, inside‑the‑equipment sensing that reveals vibration signatures, thermal behavior, acoustic patterns, alignment drift, and component wear from the machine’s point of view. Reliability teams gain a unified, multi‑sensor truth about their automation, powered by a platform engineered for continuous operation.

The cost of falling behind is steep. Unplanned downtime now averages $260,000 per hour, with major operations reporting losses up to $1.7M per hour. Across the sector, downtime drains an estimated $852M every week — capital that never returns. In environments where throughput is the business model, even a single failure can cascade into missed service levels, SLA penalties, staffing overruns, and long‑term competitive erosion.

Where Mechanical Truth Matters Most

Modern automation runs on conveyors, sorters, and baggage systems that span thousands of feet and operate at relentless duty cycles. Yet the most critical mechanical behavior — drift, friction, imbalance, heat, and alignment — happens deep inside the equipment, far beyond the reach of fixed sensors or manual inspection. TinMan Systems captures this hidden behavior from within the moving machinery itself, revealing the real conditions that determine throughput, reliability, and system health. Scroll down to see the products that make this possible.

Conveyors, From the Inside Out

Conveyors move everything — and they’re often the first place mechanical drift begins. Inside the line, TinMan captures vibration, thermal, acoustic, and alignment behavior under real load, exposing early‑stage degradation long before it impacts throughput or stability.

Learn More →Sorters, Beneath the Belt Line

High‑speed sorters operate at extreme duty cycles where friction, brush wear, wheel imbalance, and alignment drift accumulate rapidly. TinMan’s carrier‑integrated sensors capture synchronized vibration, thermal, and video data at full operating speed — revealing degradation patterns that external sensors simply cannot see.

Learn More →

Baggage Systems, Beyond the Surface

Airport baggage systems demand continuous uptime under heavy load. TinMan synchronizes thermal, vibration, acoustic, and positional data across conveyors, EDS lines, and make‑up carousels — giving operators the real‑time visibility needed to prevent jams, reduce wear, and maintain consistent passenger flow.

Learn More →The Diagnostic Systems Built to See What Automation Hides

TinMan Systems was founded on a simple truth: the only way to understand automation is to sense it from within. Our real‑time AI platform synchronizes vibration, thermal, acoustic, positional, and video data at operational speed — forming a sensing layer that captures mechanical behavior exactly as it occurs inside the equipment. These diagnostic systems are the deployed forms of that layer. Whether riding the conveyor like a package or integrated directly into a sorter carrier, each product delivers a precise, first‑person view of system health that no fixed sensor can match. Scroll down to see how they work.

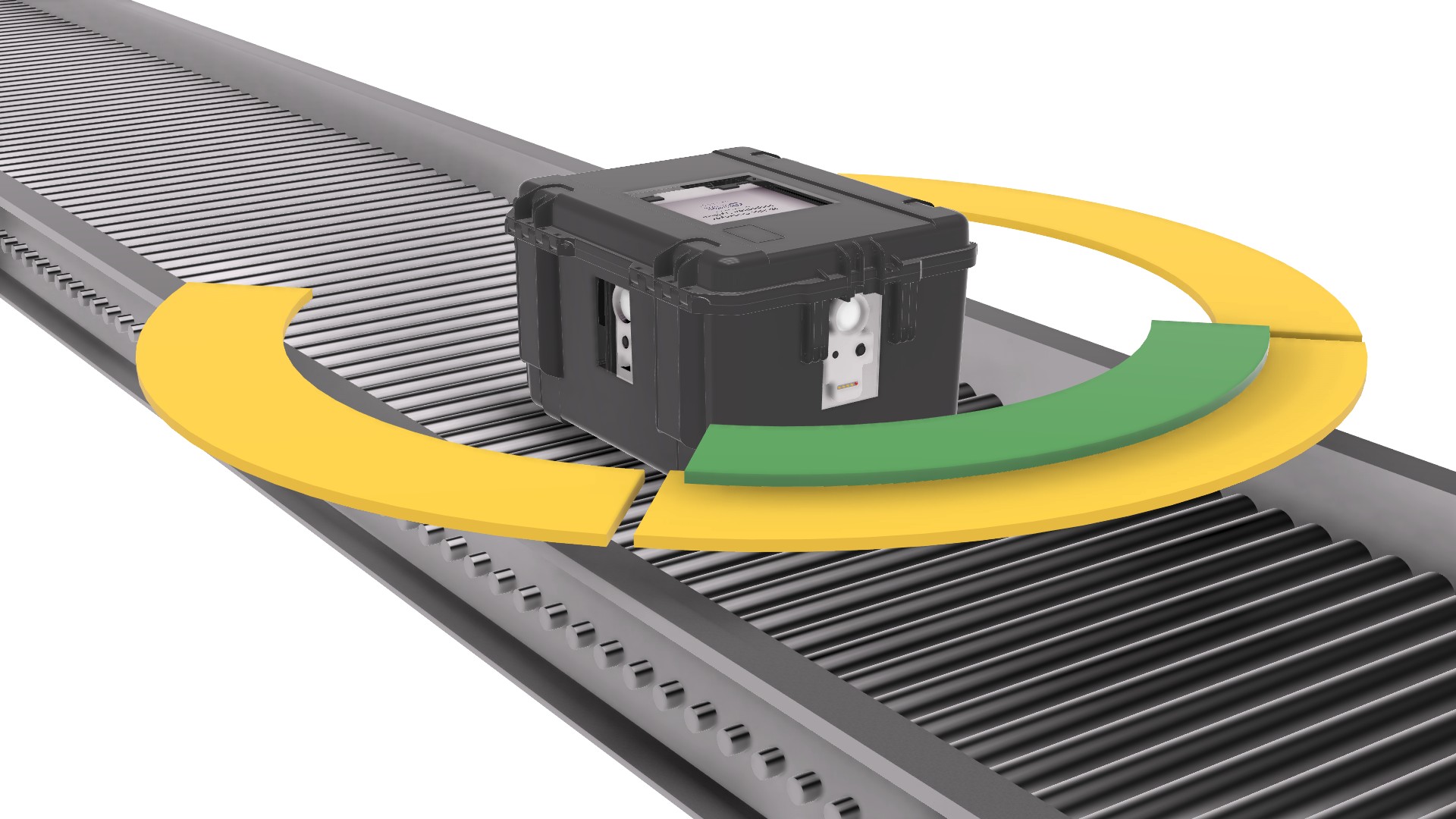

MCIS (Mobile Conveyor Inspection System)

The MCIS is TinMan’s flagship mobile inspection platform — a self‑contained, multi‑sensor unit that rides the conveyor exactly like a package, capturing synchronized vibration, thermal, acoustic, and positional data under true operating load. It reveals drift, friction, imbalance, and early‑stage wear that fixed sensors simply cannot detect, giving reliability teams the ground‑truth insight they need to validate assets, commission faster, and prevent failures before they surface.

Explore MCIS →

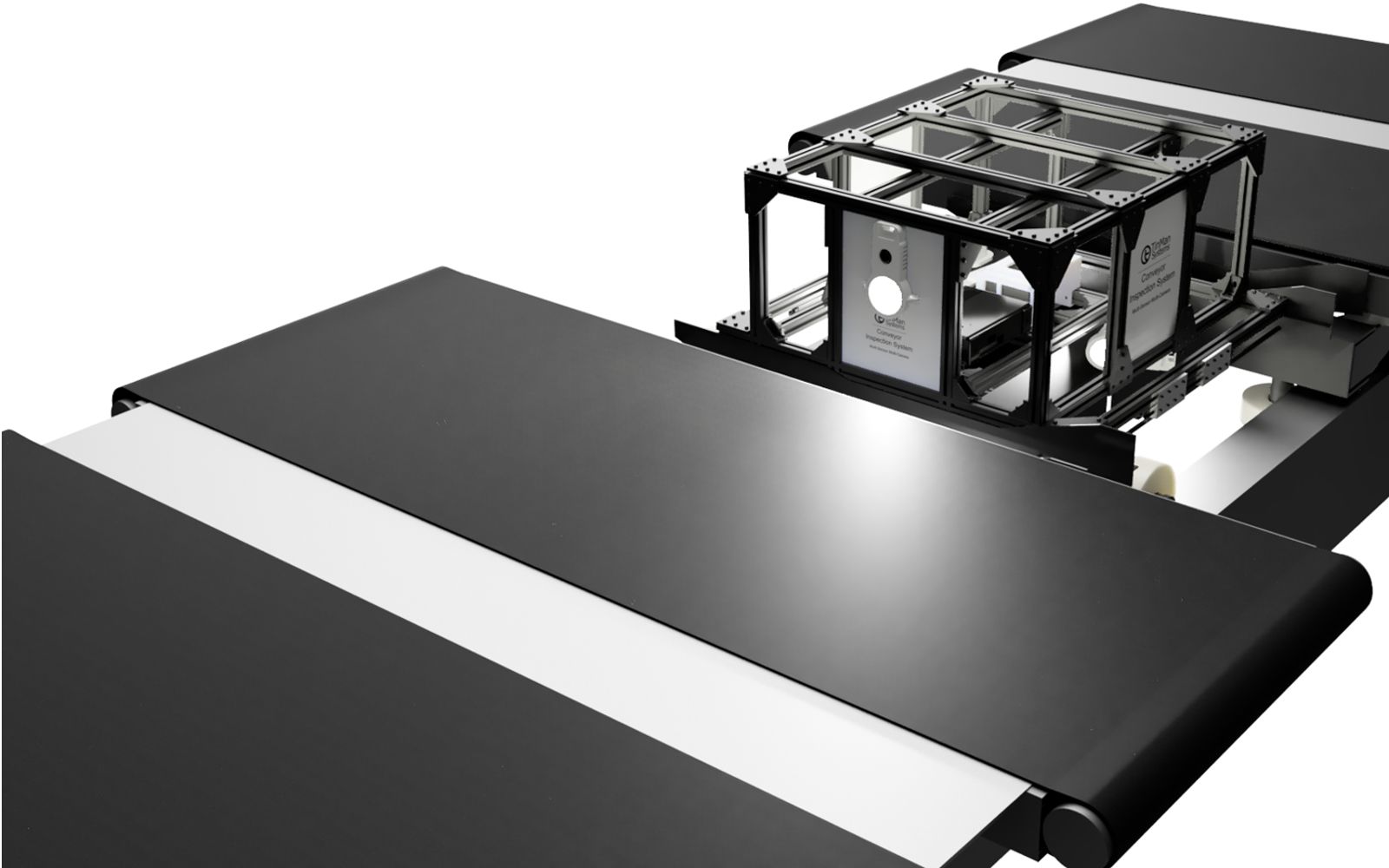

SORTERVision™

SORTERVision™ is a full MCIS unit engineered into a sorter carrier, descending its side‑mounted cameras and sensors below the crossbelt plane to capture synchronized vibration, thermal, acoustic, and video data from deep inside the system. It reveals structural issues, wiring faults, friction points, blockages, and alignment drift across sorters that often span a mile or more — delivering the same ground‑truth mechanical insight as MCIS, but from the one place no other tool can reach: the sorter’s hidden underbelly.

Explore SORTERVision™ →

Cascades Continuous Monitoring System

Cascades is TinMan Systems' continuous, wireless multi‑sensor monitoring system for large conveyors and sorters — a permanently deployed solution that captures vibration, thermal, acoustic, voltage, and positional behavior in real time. It unifies these signals into a single diagnostic stream, delivering instant alerts, trend analysis, and early detection of mechanical degradation across systems that run thousands of feet. Cascades keeps high‑volume operations stable, predictable, and operating at peak reliability.

Explore Cascades →The TinMan Systems Platform

The TinMan Systems Platform is the real‑time engine behind every diagnostic system we build — a synchronized, multi‑sensor architecture designed to capture automation from the inside out. It unifies sensing, interpretation, and reporting into one coherent environment, giving operators a complete, first‑person understanding of mechanical behavior at operational speed.

Multi‑Sensor Fusion

Vibration, thermal, video, audio, distance, and orientation — all captured in perfect sync to form a single, time‑aligned mechanical record of every run. This is the foundation that makes TinMan’s inside‑the‑equipment perspective possible.

Real‑Time Interpretation

AI‑driven detection of drift, wear, hotspots, friction spikes, imbalance, and failure precursors — computed live as the system moves. Operators see what the equipment feels, not after the fact, but as it happens.

Synchronized Reporting

Engineering‑grade session replay, raw sensor timelines, and diagnostic overlays that accelerate troubleshooting and root‑cause analysis. Every data stream is aligned to the same clock, giving teams a single source of mechanical truth.

Give your automation a real‑time understanding of itself.

Talk to an engineer, see a live demo, or explore how TinMan Systems integrates with your environment.