Why Sorter Reliability Matters

Sortation systems are the heartbeat of high‑volume logistics, retail, and manufacturing. They direct items to precise destinations at high speed, and even small mechanical deviations — friction spikes, wheel wear, brush degradation, timing drift — can cascade into misroutes, jams, or full system stoppages.

TinMan captures these early signals from inside the sorter itself, giving operators the clarity they need to maintain throughput and prevent failures across every sorter architecture.

Sortation Systems We Support

TinMan’s diagnostic systems work across the full spectrum of sortation technologies — from high‑throughput loop sorters to medium‑speed divert systems and low‑volume specialty sorters. Each architecture has unique mechanical behaviors, and TinMan captures the signatures that reveal early‑stage issues.

High Throughput Sorters (60+ sorts/min)

- Cross‑Belt Sorters: Perpendicular belts on a loop discharge items with precise timing.

- Tilt‑Tray Sorters: Trays tilt to slide items into chutes; ideal for varied product types.

- Sliding Shoe Sorters: Shoes glide along the conveyor to gently push items off.

- Narrow Belt Sorters: Angled wheels divert items at 30–90 degrees.

Medium Throughput Sorters (20–60 sorts/min)

- Pop‑Up Wheel Sorters: Wheels rise to lift and divert items perpendicularly.

- Activated Roller Bed (ARB): Powered rollers shift or elevate items for controlled diversion.

- Pivoting Arm / Paddle Sorters: Arms extend to push items onto downstream conveyors.

Low Throughput Sorters (Up to 20 sorts/min)

- Pusher Sorters: Pneumatic pushers gently move items off the belt.

- 90‑Degree Transfers: Steerable wheels or pop‑up transfers for basic routing.

Specialty Sorters - subject to review

- Bomb Bay Sorters: Trapdoor carriers for small or lightweight items.

- Pneumatic Sorters: Air bursts for lightweight or delicate products.

- Robotic Sorters: AMRs or tabletop robots for flexible, SKU‑agnostic sorting.

TinMan’s multi‑sensor platform adapts to each of these systems, capturing vibration, thermal, acoustic, and positional signatures that reveal mechanical drift long before failures occur.

Systems for Sorter Diagnostics

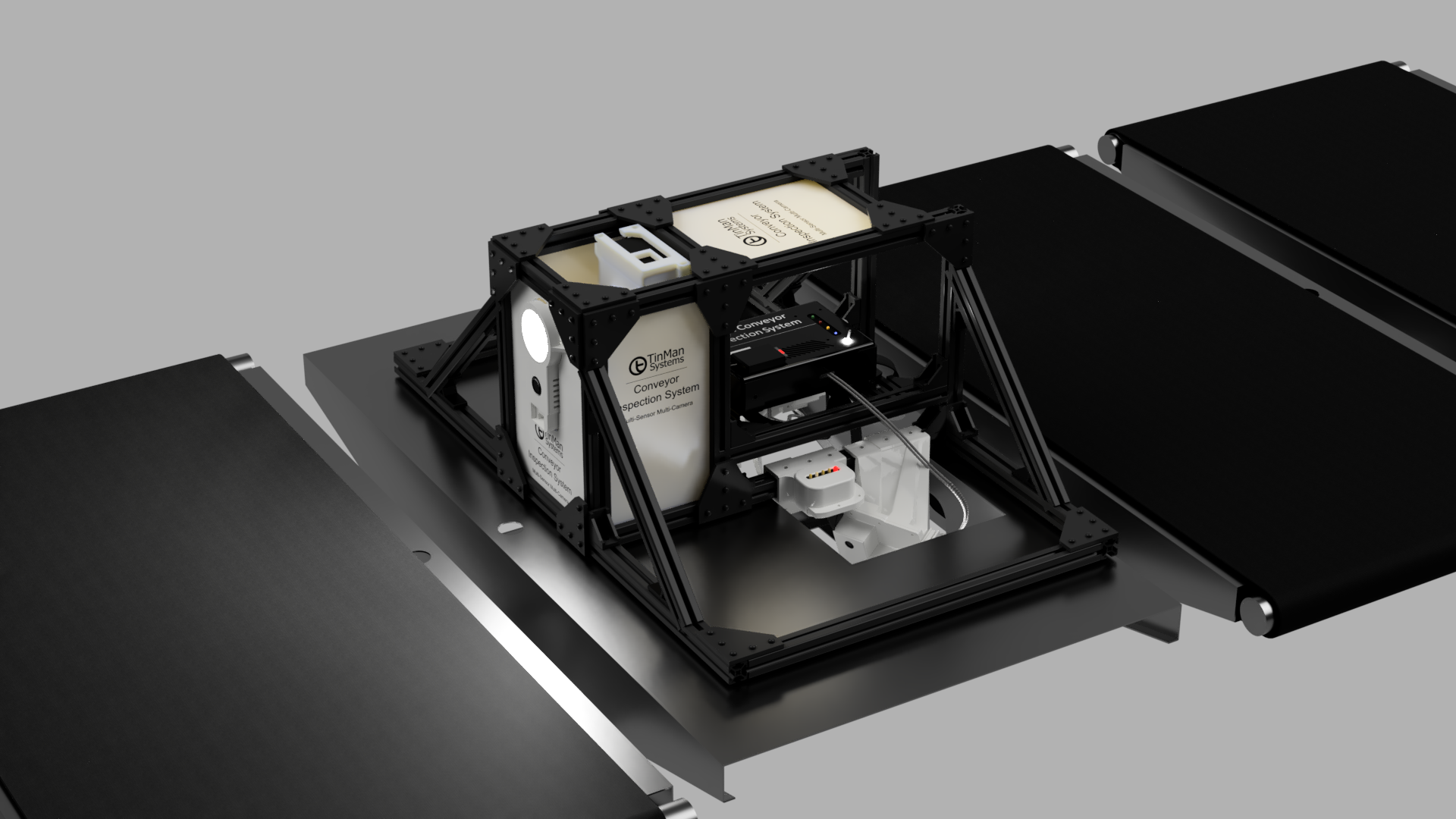

SORTERVision™

SORTERVision™ embeds synchronized video, vibration, thermal, and acoustic sensors directly into sorter carriers. It captures mechanical behavior during live operation — friction events, wheel and brush wear, alignment drift, timing anomalies — across every sorter type, from cross‑belt to sliding shoe.

Explore SORTERVision →Cascades

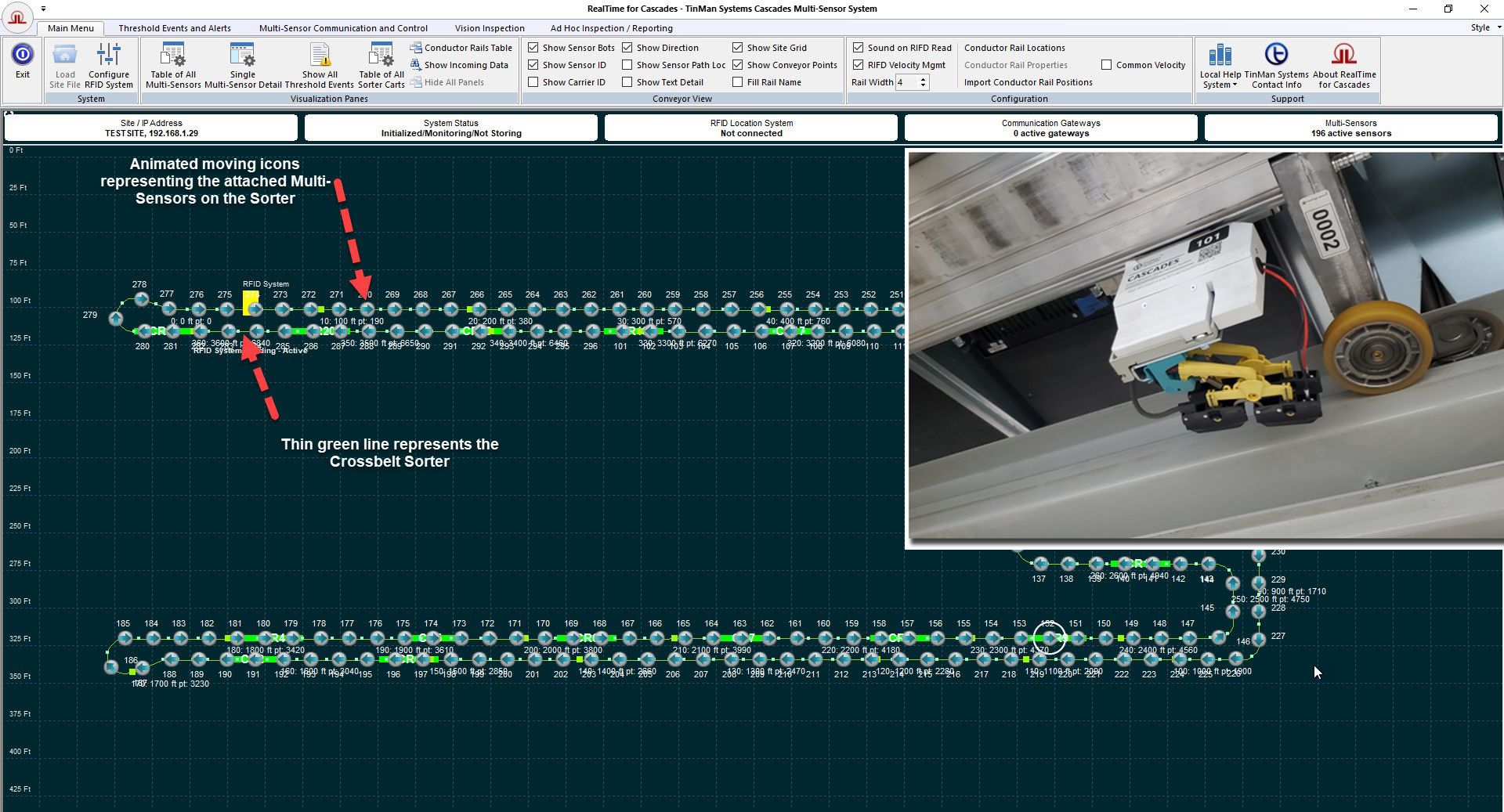

Cascades provides continuous, wireless multi‑sensor monitoring for sorter systems. Permanently mounted modules track vibration, temperature, and acoustic signatures across the sorter, enabling predictive maintenance and long‑term reliability insights for any throughput class.

Explore Cascades →