Why Conveyor Reliability Matters

Conveyors are the backbone of modern automation. They move everything—cases, totes, polybags, raw materials—and any slowdown or stoppage cascades across the entire operation. Mechanical drift often develops gradually: belt tension changes, rollers wear unevenly, bearings heat up, and alignment shifts under load. TinMan captures these early signals in real time, giving operators the clarity they need to prevent downtime and maintain throughput.

Systems for Conveyor Diagnostics

MCIS

MCIS delivers synchronized video, vibration, thermal, and acoustic diagnostics for conveyor systems. It captures belt behavior, roller condition, tracking issues, friction events, and mechanical anomalies during live operation — providing high‑resolution insight across any conveyor class or throughput level.

Explore MCIS →Cascades

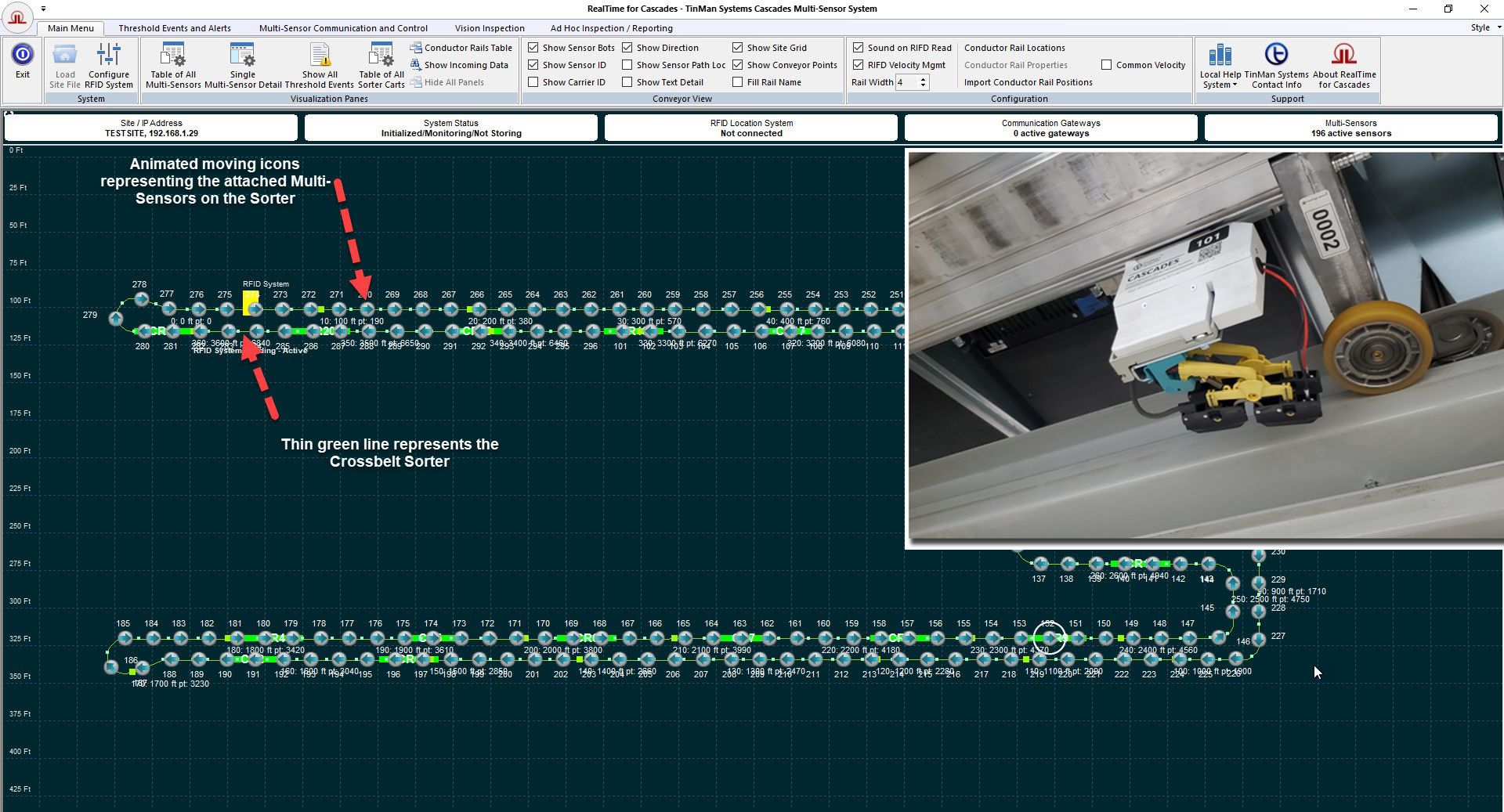

Cascades provides continuous, wireless multi‑sensor monitoring for conveyor systems. Permanently mounted modules track vibration, temperature, and acoustic signatures across the line, enabling predictive maintenance and long‑term reliability insights for any conveyor environment.

Explore Cascades →