Diagnostics Built for Modern Automation

TinMan’s product suite captures synchronized multi‑sensor data, interprets mechanical behavior, and delivers predictive insight at industrial scale. From mobile inspection runs to continuous wireless monitoring to inside‑the‑machine sorter diagnostics, each system is engineered to give operators clarity, confidence, and control over the world’s most demanding automated environments.

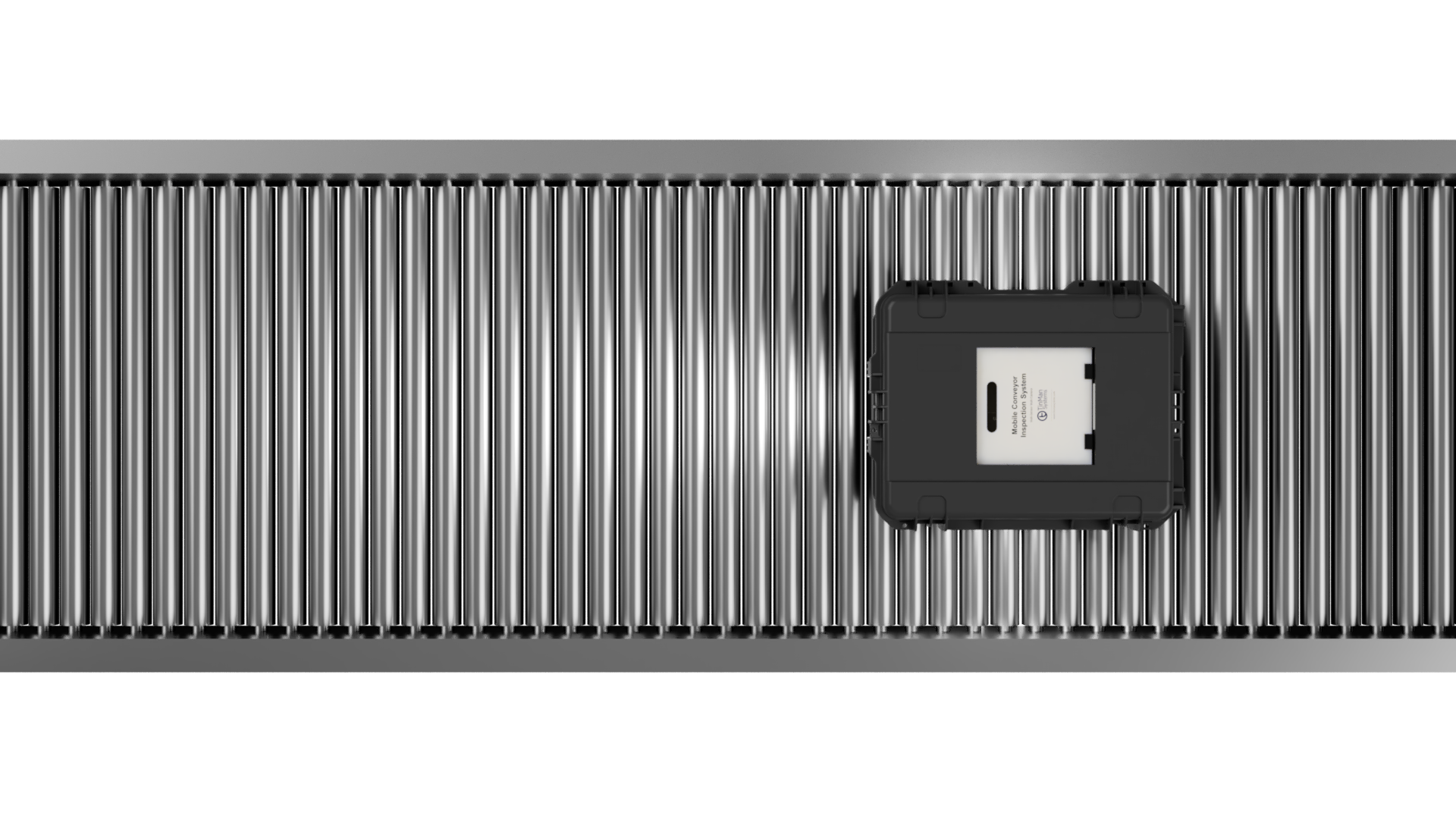

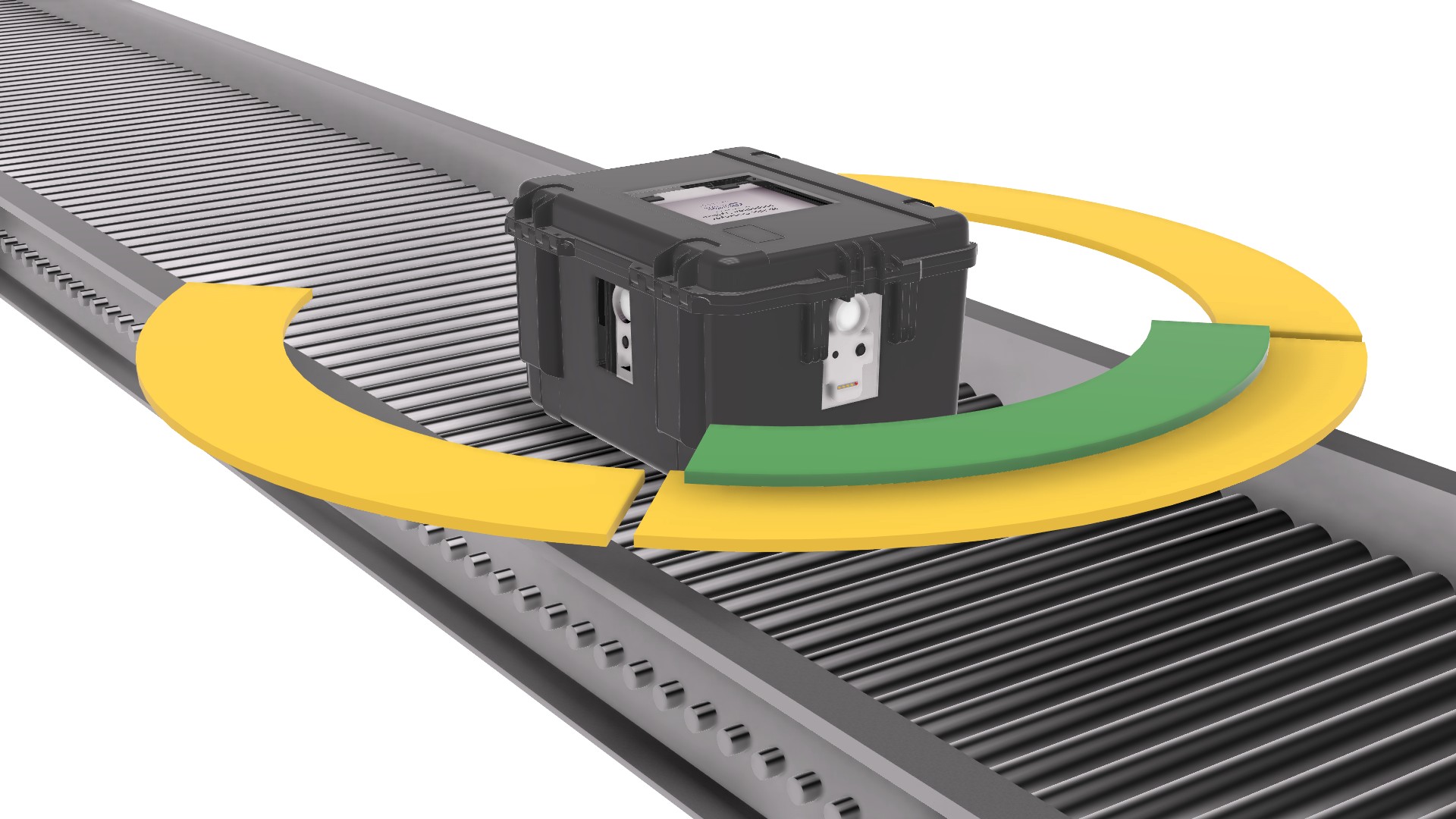

MCIS

The Mobile Conveyor Inspection System travels inside totes or cases, capturing synchronized video, thermal, vibration, acoustic, and positional data. MCIS reveals issues static sensors miss — misalignment, roller fatigue, belt drift, and load‑dependent anomalies.

Explore MCIS →

SORTERVision™

SORTERVision™ mounts directly onto sorter carriers, capturing synchronized video, thermal imaging, vibration signatures, and acoustic patterns from inside the machine. It provides unmatched visibility into high‑speed sorter behavior across multiple architectures.

Explore SORTERVision™ →

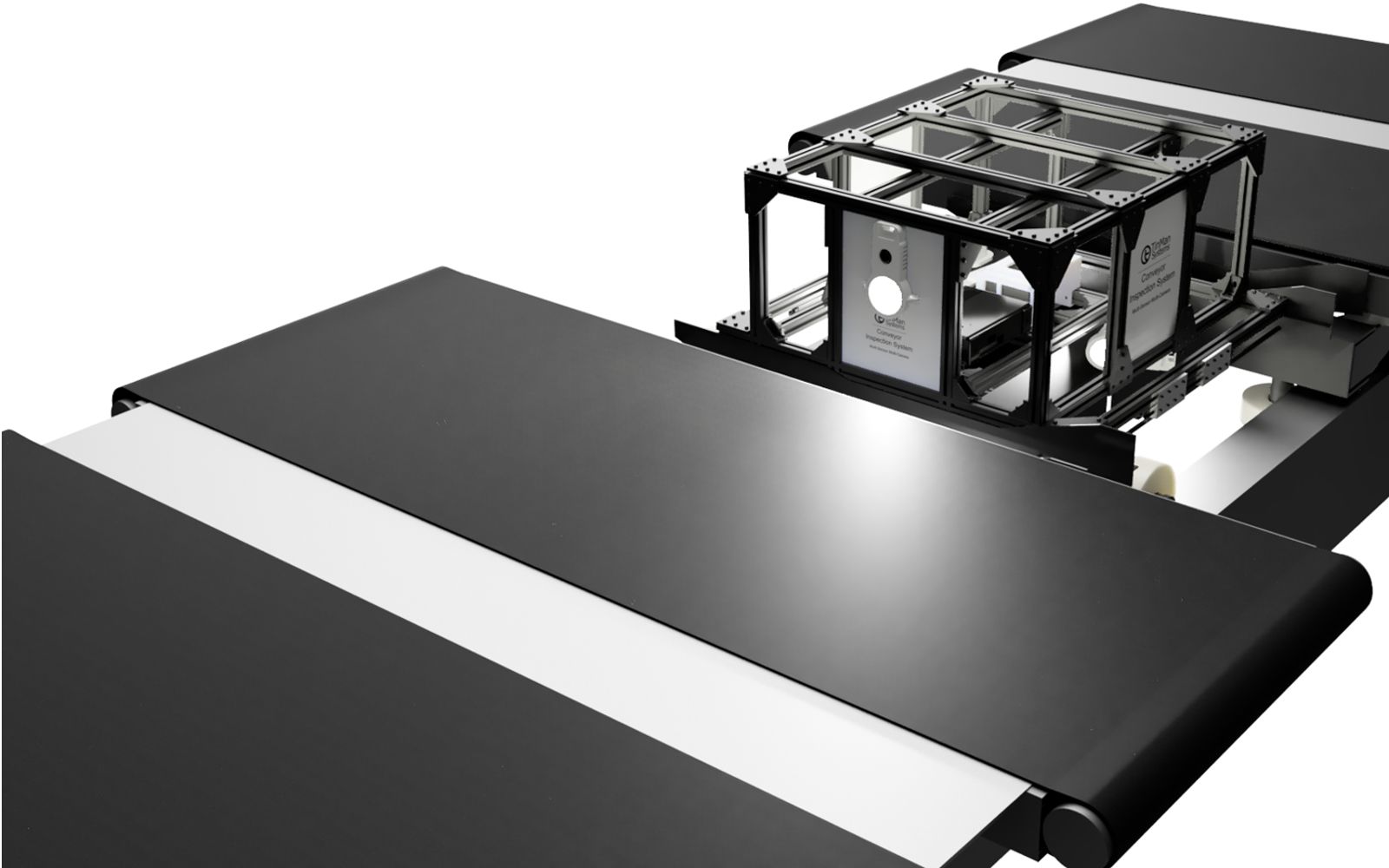

Cascades

Cascades is TinMan’s wireless, continuously monitoring multi‑sensor system for conveyors and sorters. It detects early‑stage failures, pinpoints their location, and integrates seamlessly with advanced modules like MotionAI’s Vision Inspection Tunnel.

Explore Cascades →