SORTERVision transforms a sorter into its own inspection system. Mounted directly onto a carrier, it travels the full sorter loop, capturing synchronized HD video, thermal imaging, vibration signatures, acoustic patterns, and positional data from inside the machine.

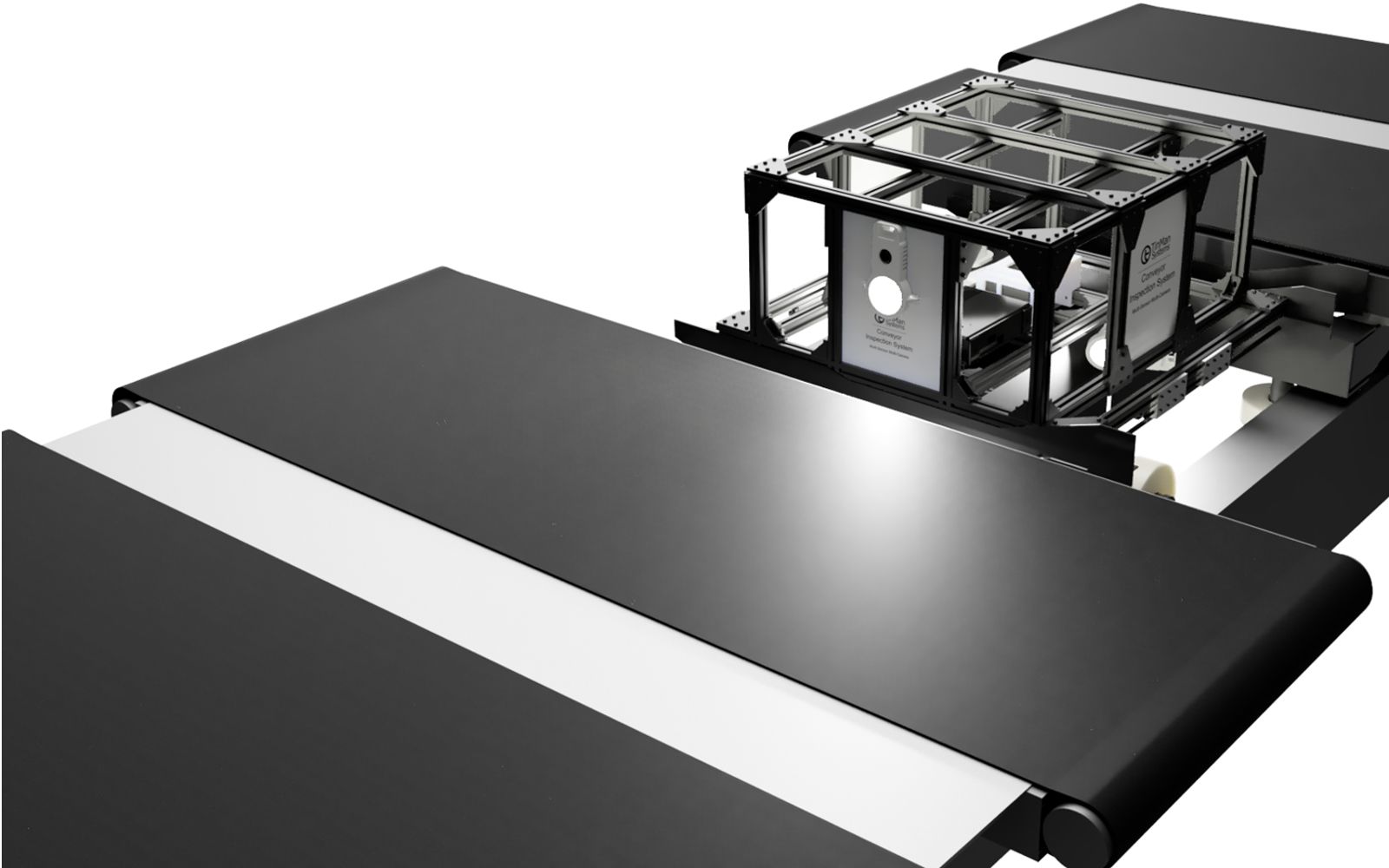

Designed for high‑throughput sorters — including crossbelt, tilt‑tray, sliding shoe, narrow belt, and other loop‑based architectures — SORTERVision provides unmatched visibility into the mechanical behavior that drives throughput. Integration is subject to mechanical review for each specific model, ensuring safe, reliable operation across diverse sorter designs.

TinMan’s multi‑sensor, multi‑camera engineering foundation extends directly into the SORTERVision platform.

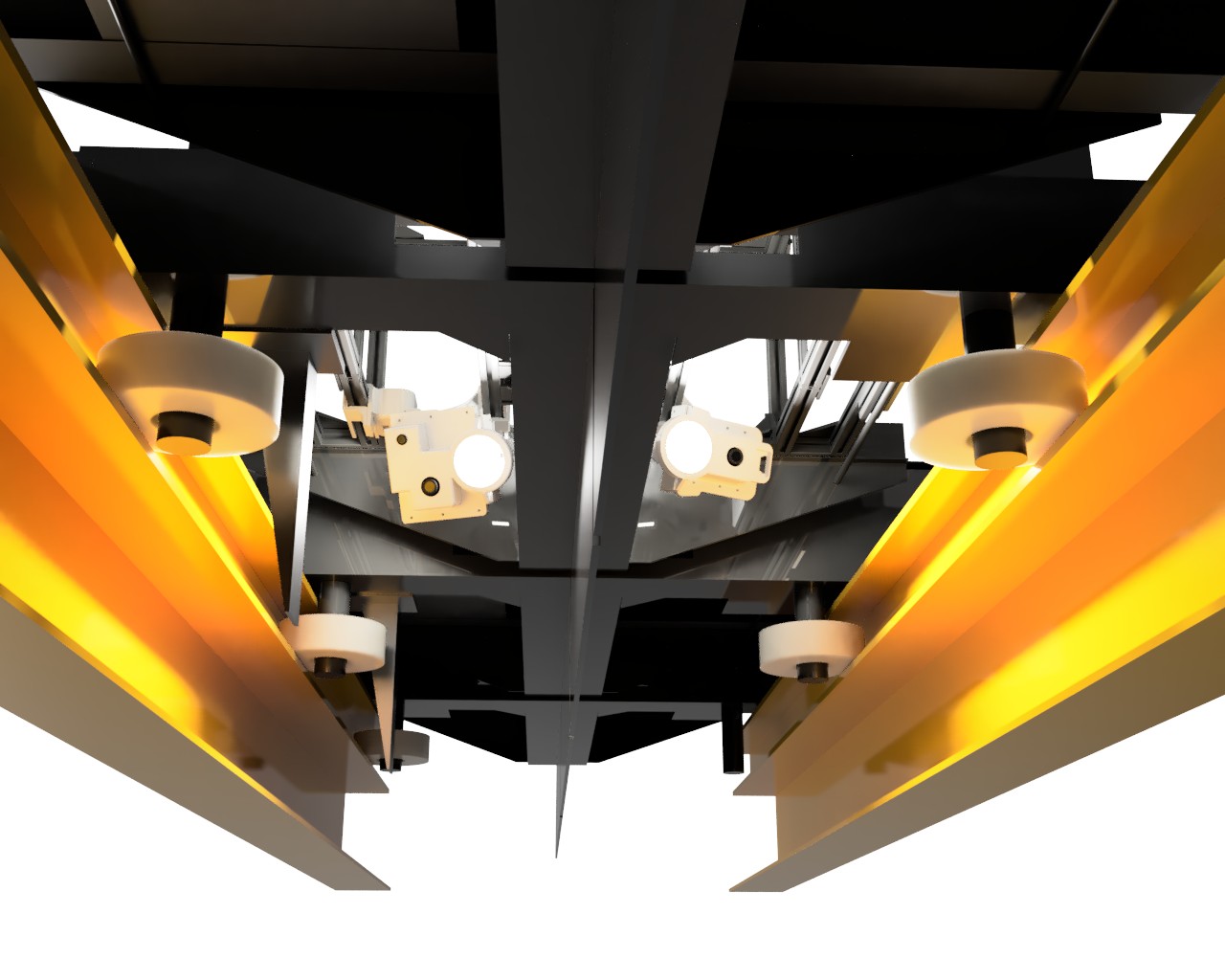

SORTERVision™ captures the sorter’s internal mechanics from the carrier’s point of view, revealing wheel behavior, brush contact, belt interfaces, and structural alignment.

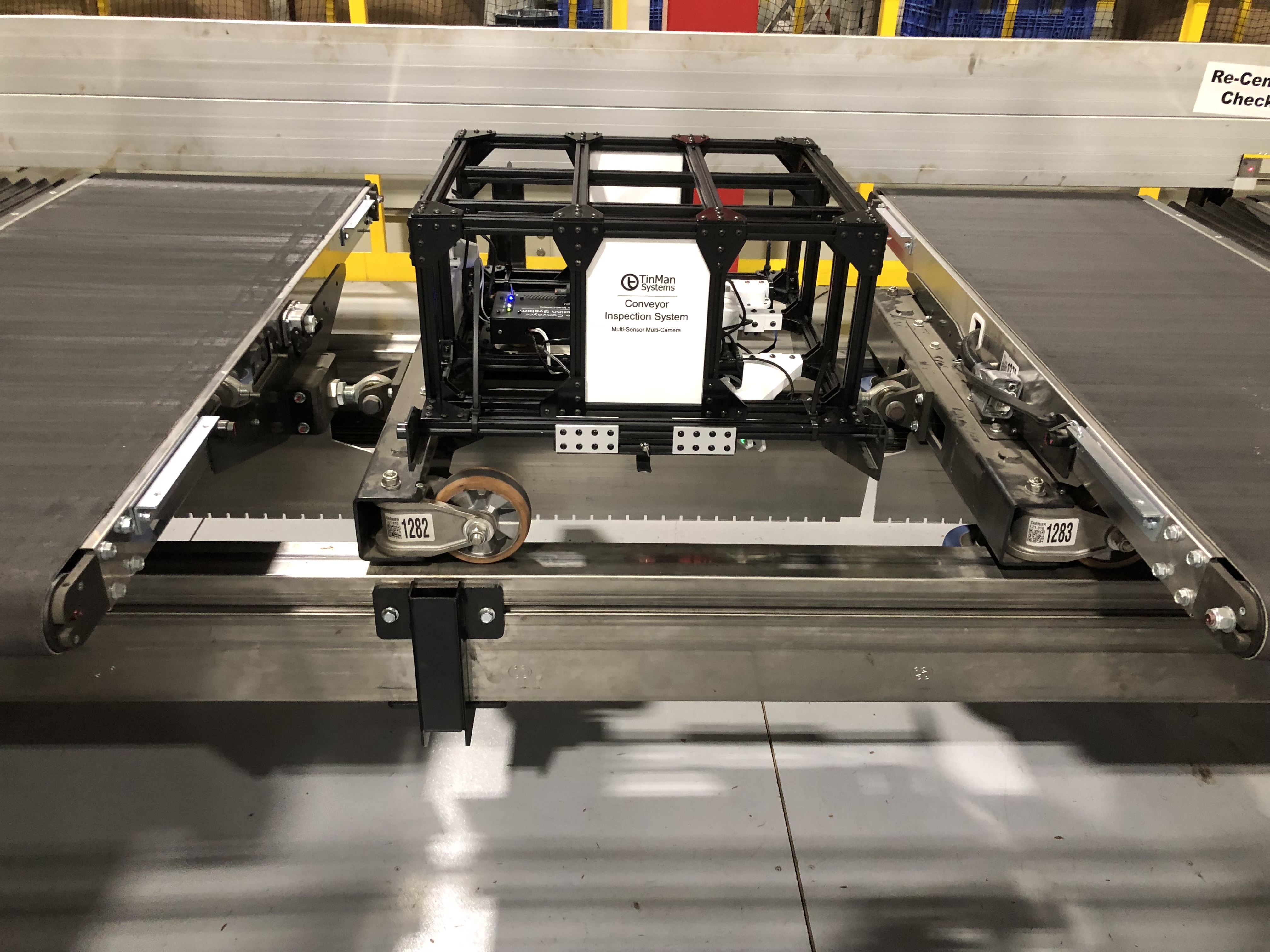

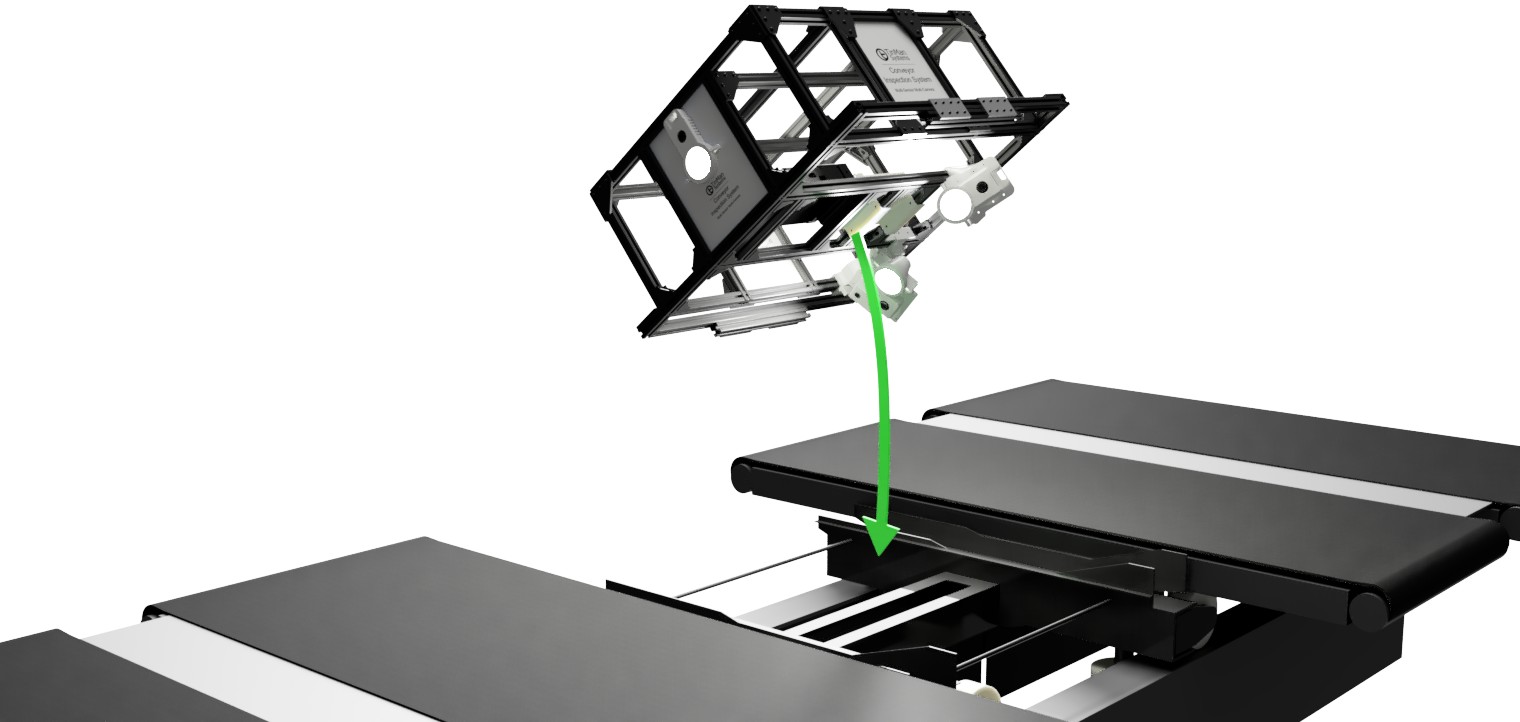

SORTERVision™ attaches directly to a sorter carrier, becoming part of the machine itself. Once mounted, it begins its continuous surveillance of the sorter’s internal environment, capturing the intricate motion of wheels, brushes, belts, motors, and conductor rails from every angle.

Three HD cameras provide a complete internal view — a forward‑facing camera above the carrier, and two interior cameras capturing the left and right underside walls. A thermal vision camera monitors conductor brush assemblies and motor housings, revealing heat buildup and friction events invisible to the naked eye.

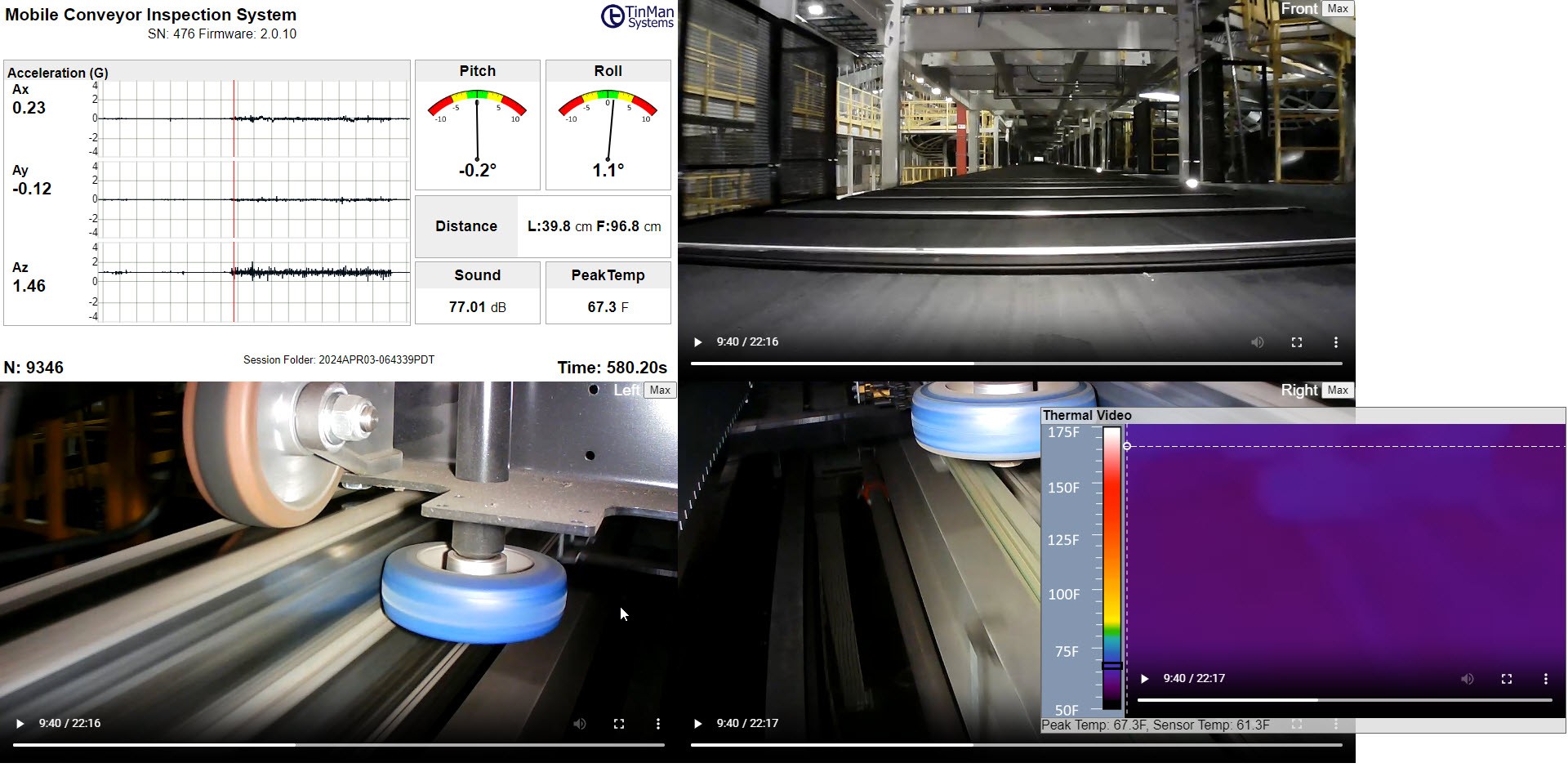

As the sorter navigates its loop, SORTERVision records sensor readings at 10–20 samples per second, synchronized with all video and thermal streams. Vibration signatures, pitch and roll, sound levels, temperature, and distance measurements are fused into a single, time‑aligned record.

Each frame is enriched with diagnostics, bookmarks, precise timestamps, and sample numbers — creating a millisecond‑accurate picture of the sorter’s mechanical health.

Multi‑camera architecture enables synchronized visual coverage of internal sorter mechanics, brush assemblies, and belt interfaces.

Camera positioning geometry provides full coverage of the sorter’s interior walls, conductor rails, and mechanical interfaces.

SORTERVision™ captures a synchronized suite of video, thermal, and sensor channels as it travels the sorter loop. All streams are sampled 10–20 times per second and aligned to the millisecond for precise mechanical analysis.

Forward HD Camera

Captures the sorter’s path ahead, wheel behavior, and carrier‑to‑carrier transitions.

Left & Right Underside Cameras

Provide full visibility of interior walls, brushes, belts, and mechanical interfaces.

Thermal Vision Camera

Monitors conductor brushes, motors, and friction points for heat buildup and wear.

3‑Axis Vibration

Detects bearing wear, wheel imbalance, impacts, and structural anomalies.

Pitch & Roll

Tracks carrier orientation, alignment drift, and mechanical oscillation.

Sound Levels (dB)

Acoustic signatures reveal grinding, rubbing, and stress events.

Temperature

Thermal sensor readings complement the thermal video stream.

Distance / Proximity

Measures wall spacing and detects obstructions or geometry changes.

Precision‑engineered mounting ensures SORTERVision™ integrates safely and securely with each sorter’s carrier geometry.

SORTERVision™ is mechanically adapted to each sorter model to ensure safe, reliable operation. TinMan Systems performs a detailed mechanical review for every deployment, evaluating carrier geometry, mounting points, clearances, conductor rail alignment, and OEM‑specific constraints.

This process ensures SORTERVision™ becomes a natural extension of the sorter’s carrier — maintaining balance, preserving throughput, and avoiding interference with wheels, brushes, belts, and conductor assemblies.

- Carrier geometry and mounting points

- Clearance around wheels, brushes, and belts

- Conductor rail alignment and brush contact

- Weight distribution and balance

- Cable routing and protection

- OEM‑specific mechanical constraints

Once integrated, SORTERVision™ travels the sorter loop as if it were a native carrier — capturing internal mechanical behavior without altering the machine’s dynamics.

Wheel Wear & Imbalance

Detects wobble, flat spots, and alignment drift through vibration and visual signatures.

Brush Contact Issues

Thermal imaging reveals heat buildup from poor conductor brush alignment or friction.

Belt & Rail Interference

Sidewall cameras capture rubbing, scraping, and geometry changes along the loop.

Carrier Oscillation

Pitch, roll, and vibration data expose oscillation patterns caused by mechanical wear.

Acoustic Stress Events

Sound signatures identify grinding, impacts, and structural resonance.

Thermal Hotspots

Thermal vision highlights friction, motor load, and conductor rail anomalies.

Each SORTERVision™ run produces a synchronized dataset containing HD video, thermal imaging, vibration signatures, acoustic patterns, and positional data. All channels are aligned to the millisecond and enriched with bookmarks, diagnostics, and threshold events.

- HD video (forward, left, right)

- Thermal video stream

- 3‑axis vibration

- Pitch & roll

- Sound levels (dB)

- Temperature

- Distance / proximity

- Threshold events

- User bookmarks

Output is compatible with the MCIS Session Analyzer, enabling frame‑accurate review, threshold navigation, and multi‑sensor correlation.

SORTERVision supports a wide range of high‑throughput sorter architectures. Integration is subject to mechanical review for each specific model.

Crossbelt Sorters

Full internal visibility of belts, wheels, and brush assemblies.

Tilt‑Tray Sorters

Captures tray motion, carrier transitions, and mechanical interfaces.

Sliding Shoe Sorters

Monitors shoe alignment, rail geometry, and friction points.

Narrow Belt Sorters

Reveals belt tracking, roller behavior, and structural alignment.

Loop‑Based Architectures

Supports any continuous‑loop sorter with carrier‑based motion.

Form factors adapt SORTERVision™ to diverse sorter geometries and OEM‑specific constraints.

SORTERVision™ is available in multiple form factors to accommodate different carrier geometries, clearances, and mechanical constraints. Custom variants can be produced for OEM‑specific requirements.

- Standard carrier‑mounted module

- Low‑profile variant for tight clearances

- Thermal‑enhanced variant

- Extended battery variant

- OEM‑specific custom housings

Bring SORTERVision™ to Your Facility

Transform your sorter into its own diagnostic system. Capture the data that matters — from inside the machine.

Contact TinMan Systems