Why Baggage Handling Reliability Matters

Airport baggage handling systems are among the most complex conveyor networks in the world. They operate continuously, often at speeds exceeding 2 meters per second, and must maintain near‑perfect accuracy to avoid delays, misroutes, and passenger dissatisfaction.

The industry has made major strides — mishandled baggage rates dropped to 0.6% in recent years — but rising passenger volumes and post‑pandemic surges have pushed systems back toward 0.8% mishandling. With global air travel expanding and smart‑airport initiatives accelerating, reliability is more critical than ever.

TinMan provides the real‑time mechanical clarity airports need to maintain throughput, reduce downtime, and support the next generation of automated baggage systems.

Industry Trends Shaping Baggage Systems

- High‑speed conveyors now process up to 6,000 bags per hour, increasing mechanical stress on belts, bearings, and transfers.

- Energy‑efficient conveyor belts can reduce system‑wide energy consumption by 40%, but require precise alignment and monitoring.

- RFID adoption delivers 99.98% read accuracy, but mechanical issues still cause jams and misroutes that tracking alone cannot prevent.

- AI‑driven predictive maintenance is projected to grow at 11.87% CAGR, reducing unplanned downtime by up to 90%.

- Destination Coded Vehicles (DCVs) — up to 5× faster than traditional conveyors — are expanding rapidly in large international airports.

TinMan’s multi‑sensor platform complements these advancements by revealing the mechanical behavior behind every belt, roller, diverter, and EDS segment — ensuring airports get the full benefit of their technology investments.

Systems for Baggage Handling Diagnostics

MCIS

The Mobile Conveyor Inspection System travels through baggage lines, capturing synchronized vibration, thermal, acoustic, and positional data. MCIS identifies misalignment, belt drift, roller fatigue, and EDS‑related mechanical stress that static sensors often miss.

Explore MCIS →Cascades

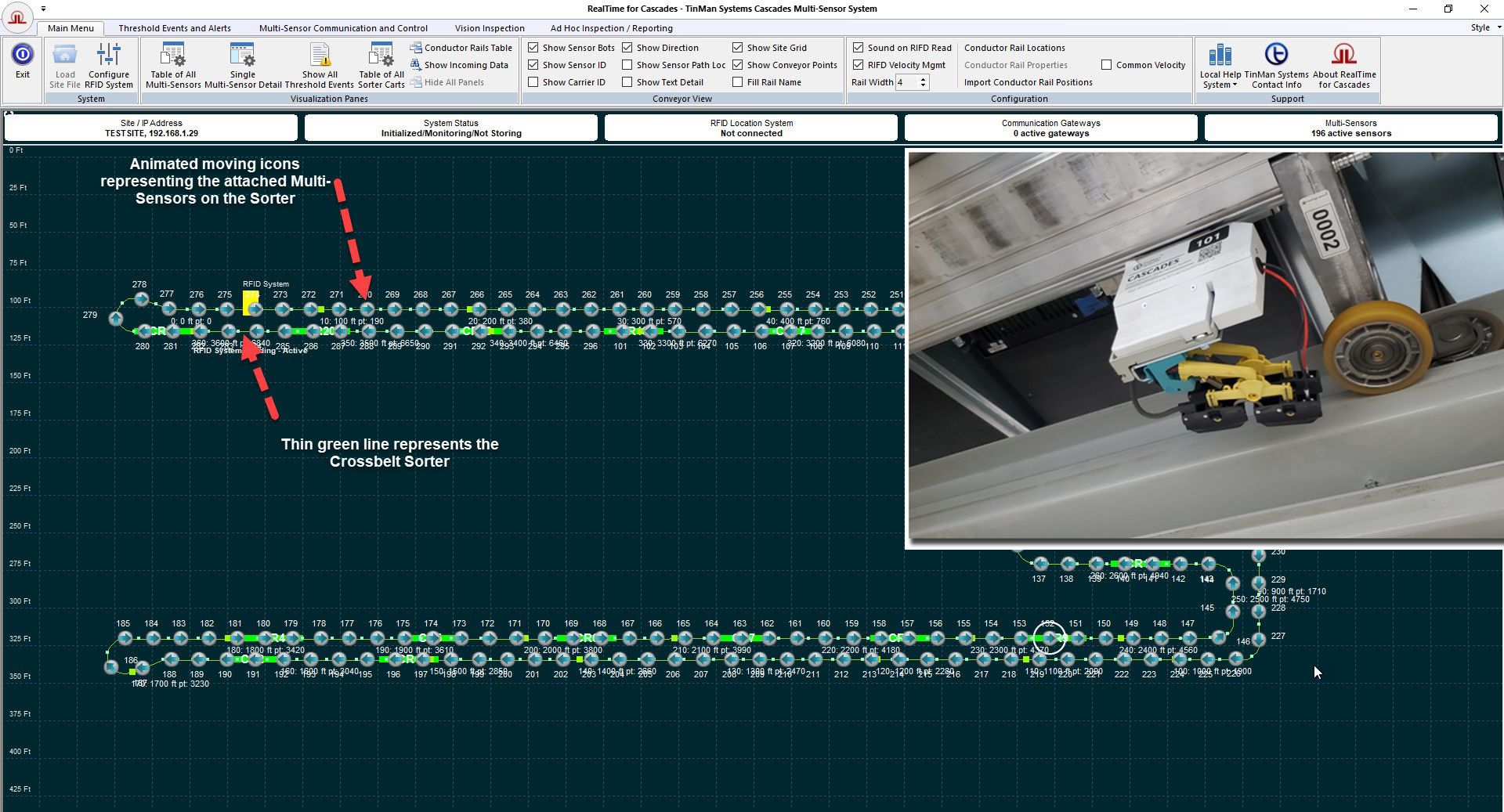

Cascades provides continuous, wireless multi‑sensor monitoring across long‑distance conveyors, EDS lines, and make‑up carousels. It detects early‑stage bearing wear, heat buildup, and vibration anomalies — enabling predictive maintenance and reducing operational delays.

Explore Cascades →