Overview

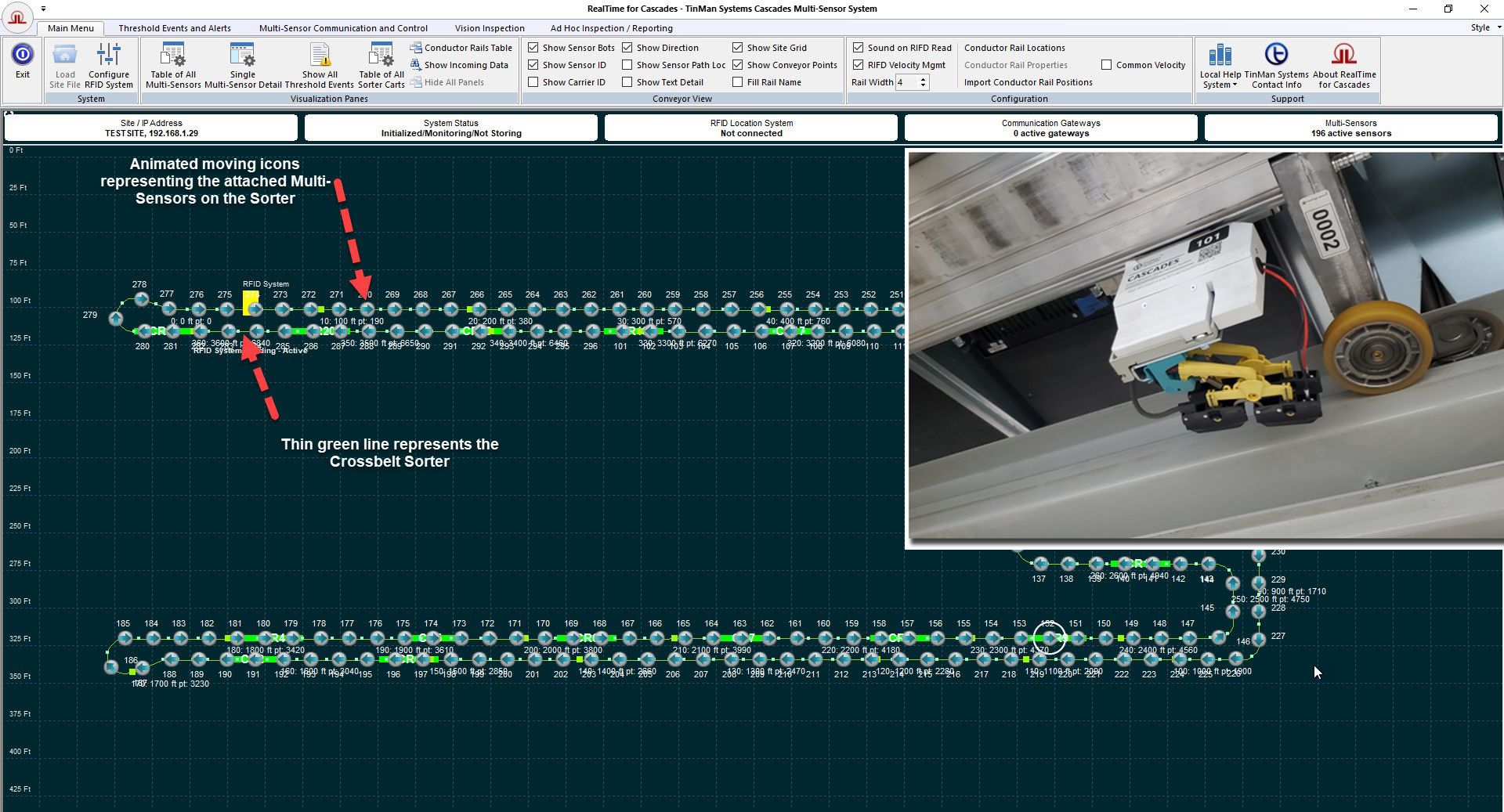

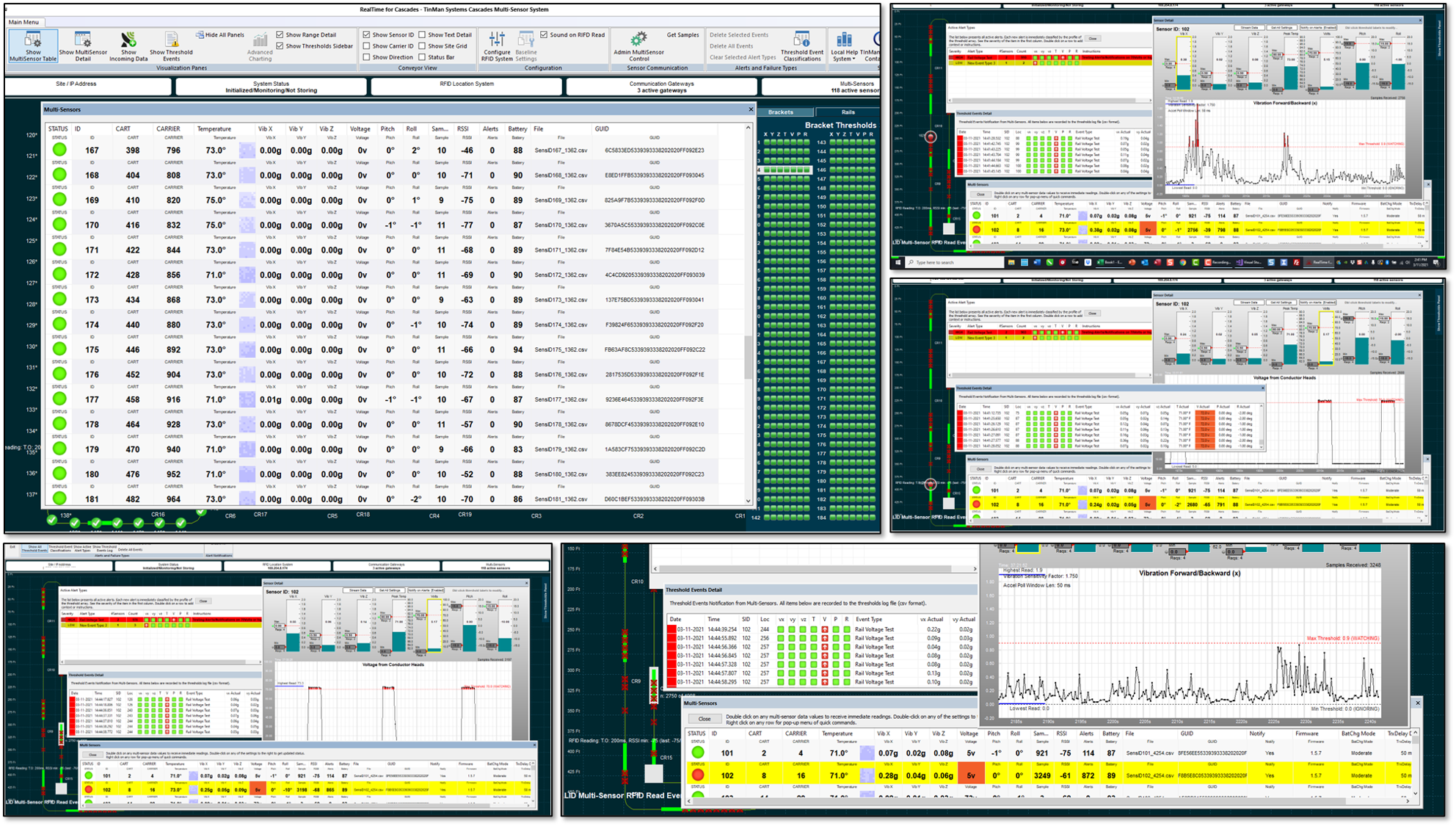

Cascades is TinMan’s continuous, real‑time monitoring system for conveyors and sorters, delivering a live, animated view of the entire machine and every carrier in motion. The Cascades Base Station visualizes the system as it runs — streaming synchronized sensor data, thermal and vibration signatures, voltage and orientation readings, and integrated camera imaging. Machine‑vision interpretation and diagnostic overlays reveal emerging issues instantly, while live alerts, severity markers, and event tracking show exactly what is happening, where it is happening, and how it is evolving in real time.

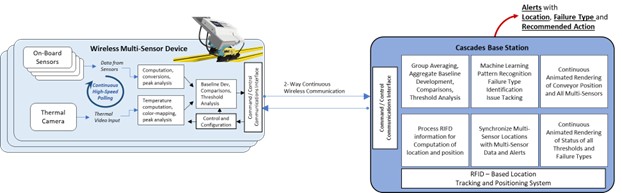

Each Cascades sensor module combines multi‑axis vibration sensing, thermal monitoring, voltage measurement, orientation tracking, and optional auxiliary sensors. Through two‑way wireless communication, Cascades synchronizes all sensor data with precise location information, giving operators a complete, moment‑by‑moment understanding of system health.

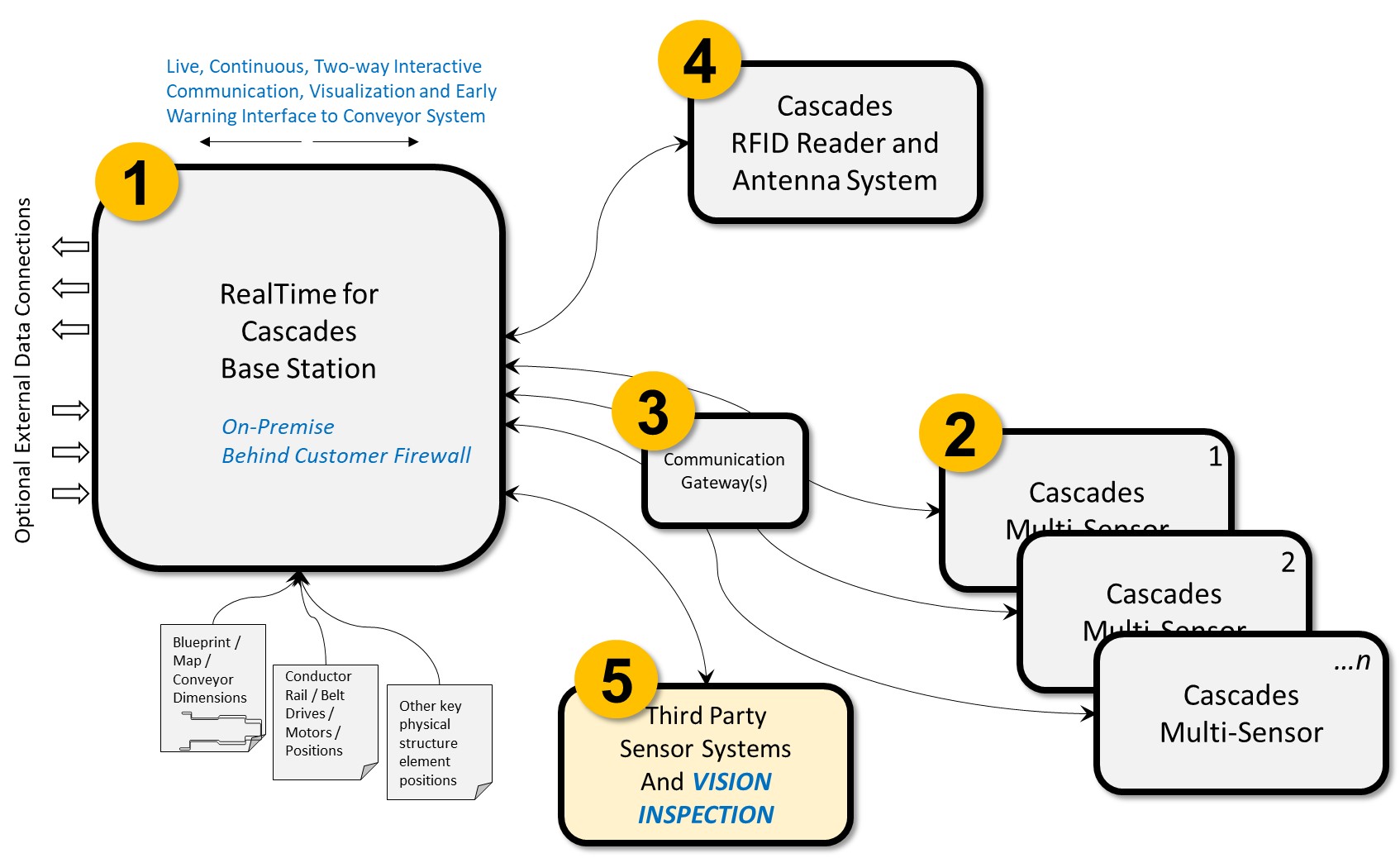

How It Works

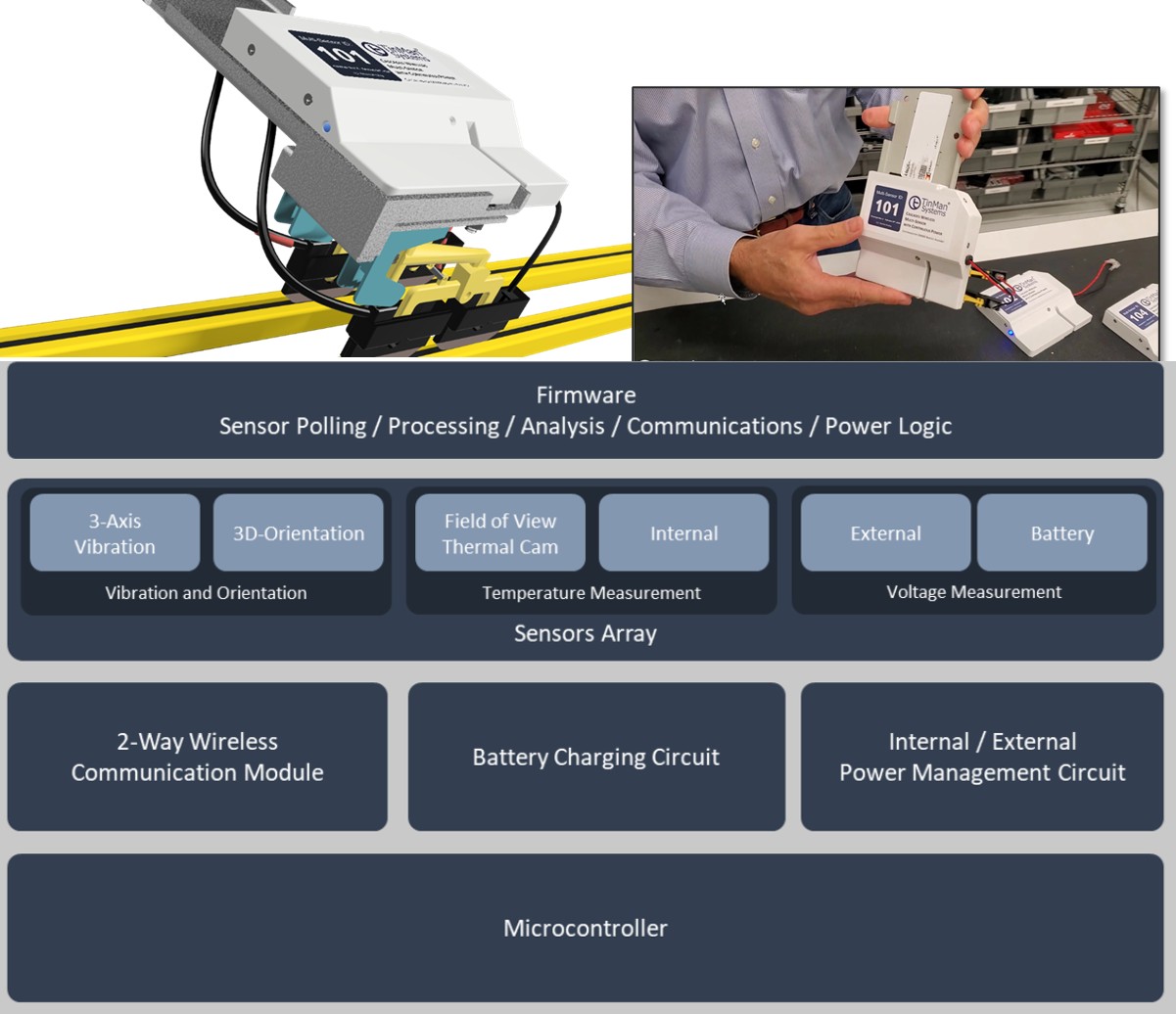

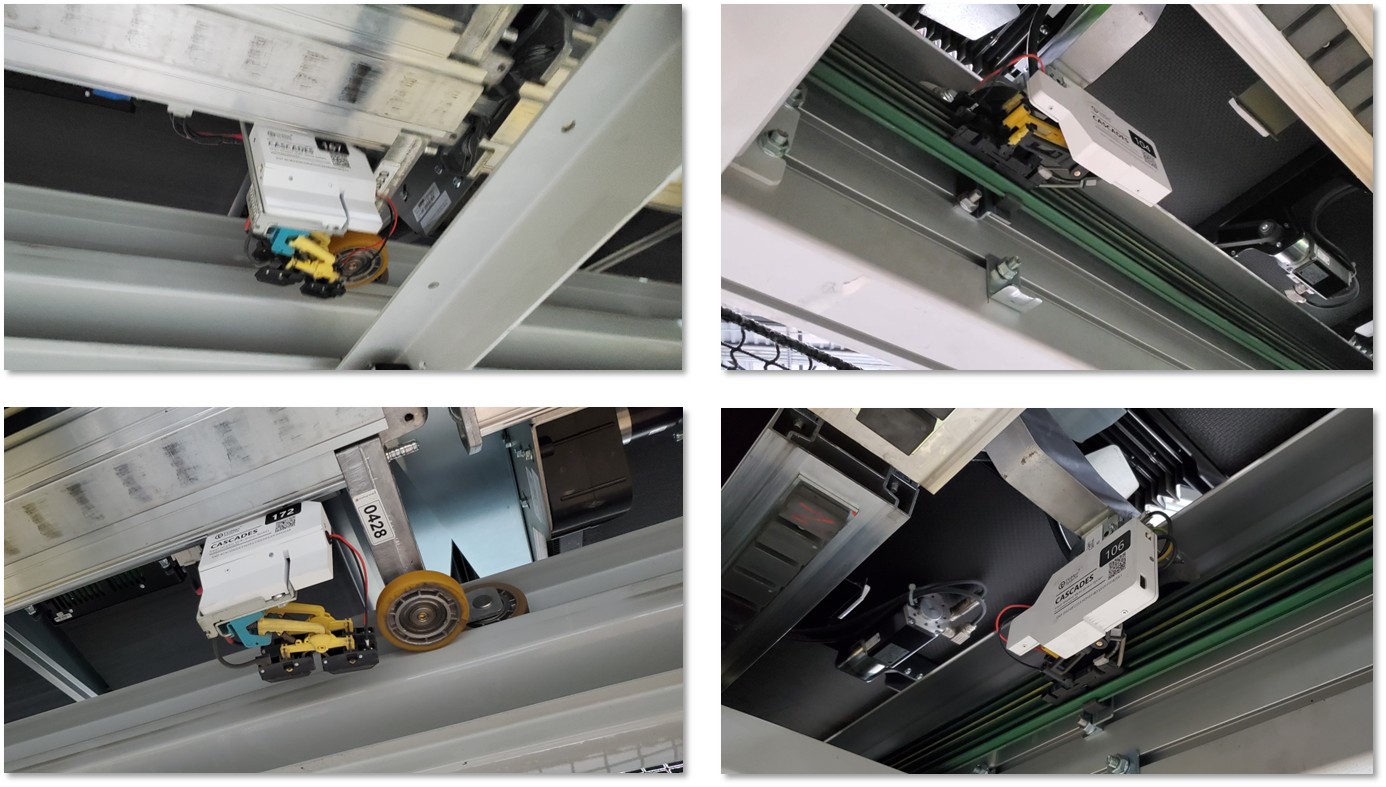

Each Cascades multi‑sensor module attaches magnetically to the conductor brush bracket of every 12th carrier, streaming synchronized 3‑axis vibration, thermal video of conductor brush heads, voltage, and pitch/roll data in real time. Modules remain continuously powered and transmit data on demand or when thresholds are exceeded.

The Cascades Base Station fuses all incoming sensor data with RFID‑based location tracking, applies machine‑learning models to classify anomalies, and renders a live animated view of the sorter and its carriers. Diagnostic overlays, alerts, and event tracking give operators immediate clarity into what is happening, where it is happening, and how severe it is.

Main Components

- Cascades Base Station Software

- Cascades Smart Wireless Multi‑Sensors

- Cascades Gateway Devices

- Cascades RFID‑Based Location System

Each multi‑sensor attaches directly to conveyor brackets or brush assemblies and houses a microcontroller, wireless module, power circuit, and an array of sensors including vibration, thermal, voltage, and orientation. These modules operate as a distributed diagnostic network across the entire conveyor or sorter.

Sensor Measurements

- 3‑Axis Vibration: forward/backward, lateral, and vertical forces

- Thermal Grid: rear‑facing 64‑pixel thermal array monitoring conductor brush heads

- Voltage: continuous measurement across conductor rails

- Orientation: pitch and roll of the bracket assembly

All measurements are synchronized with RFID location data, enabling precise diagnostics of both moving components and fixed conveyor structures.

Session Output

The Cascades Base Station continuously parses, records, and analyzes incoming sensor data. Threshold events are classified into failure types using machine learning, and outputs are presented through real‑time dashboards and exportable engineering files:

- HTML Viewer: interactive visualization of sensor data, thresholds, and location tracking

- CSV Raw Data: complete dataset for engineering and reliability analysis

Integration & Adaptability

Cascades is designed for extensibility. Each sensor module can be customized with additional sensors, alternate form factors, or specialized mounting hardware. With seven onboard measurements and support for three auxiliary sensors, the electronics are smaller than a credit card — enabling deployment across conveyors, sorters, and other industrial assets.

The Cascades Base Station extends this adaptability by integrating external systems such as the MotionAI Vision Inspection Tunnel. Through TinMan RealTime, the Base Station supports multiple simultaneous connections (TCP/IP, UDP, Serial/USB, or wireless) and provides a multi‑threaded visualization interface with multiple live viewing panes.

Cascades employs patented auto‑configuration and real‑time virtual mapping of physical systems, allowing new equipment types to be added quickly based on their physical characteristics and initial configuration.

Supported Sorter Types

Cascades currently supports:

- Intelligrated

- Beumer

- MHS Fortna

- Vanderlande

- Dematic

If your operation uses another sorter type, TinMan Systems can adapt Cascades to support it — ensuring seamless integration across diverse environments.

Typical Findings

Brush & Bracket Misalignment

Detected through vibration signatures, thermal deviation, and orientation drift.

Excessive Vibration Spikes

Identified through 3‑axis vibration analysis and threshold‑based event detection.

Thermal Hotspots

Non‑contact thermal video reveals overheating conductor brush heads in real time.

Voltage Irregularities

Continuous voltage monitoring exposes rail inconsistencies and electrical drift.

Orientation Drift

Pitch/roll changes indicate mechanical looseness or bracket deformation.

Stuck Packages / Amnesty Events

Identified when multiple multi‑sensors report vibration anomalies at the same physical location along the sorter, using synchronized RFID‑based position mapping to pinpoint the obstruction.

Loose Bracket Housings

Detected when a single multi‑sensor shows continuous vibration instability over time, indicating mechanical looseness or bracket fatigue.