Why These Solutions Exist

High-throughput automation moves fast, operates under stress, and degrades silently. Traditional monitoring tools show symptoms, not causes—and rarely at the speed operators need. TinMan Systems delivers real-time mechanical truth from inside the equipment, giving teams the clarity required to maintain throughput and prevent failures before they occur.

Powered by the TinMan Platform

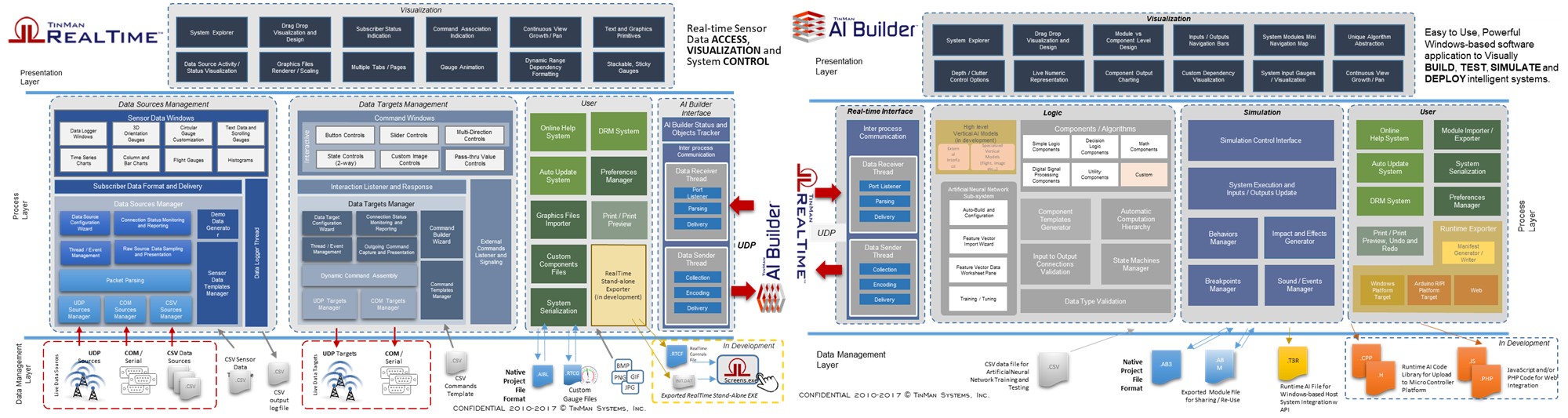

Every TinMan solution is built on a unified real-time architecture engineered for automated, high-speed environments. At its core are two complementary systems:

- RealTime Engine: a multi-threaded, sensor-agnostic environment for high-frequency data acquisition, synchronization, and visualization.

- AI Builder Logic: a modular decision framework that interprets mechanical behavior, detects anomalies, and supports predictive maintenance.

Together, they form a scalable foundation for smart firmware, software, and middleware—delivering precise diagnostics across the world’s most demanding operations.

Where TinMan Systems Delivers Value

Real-time diagnostics for the environments where uptime, reliability, and throughput matter most.

Conveyors

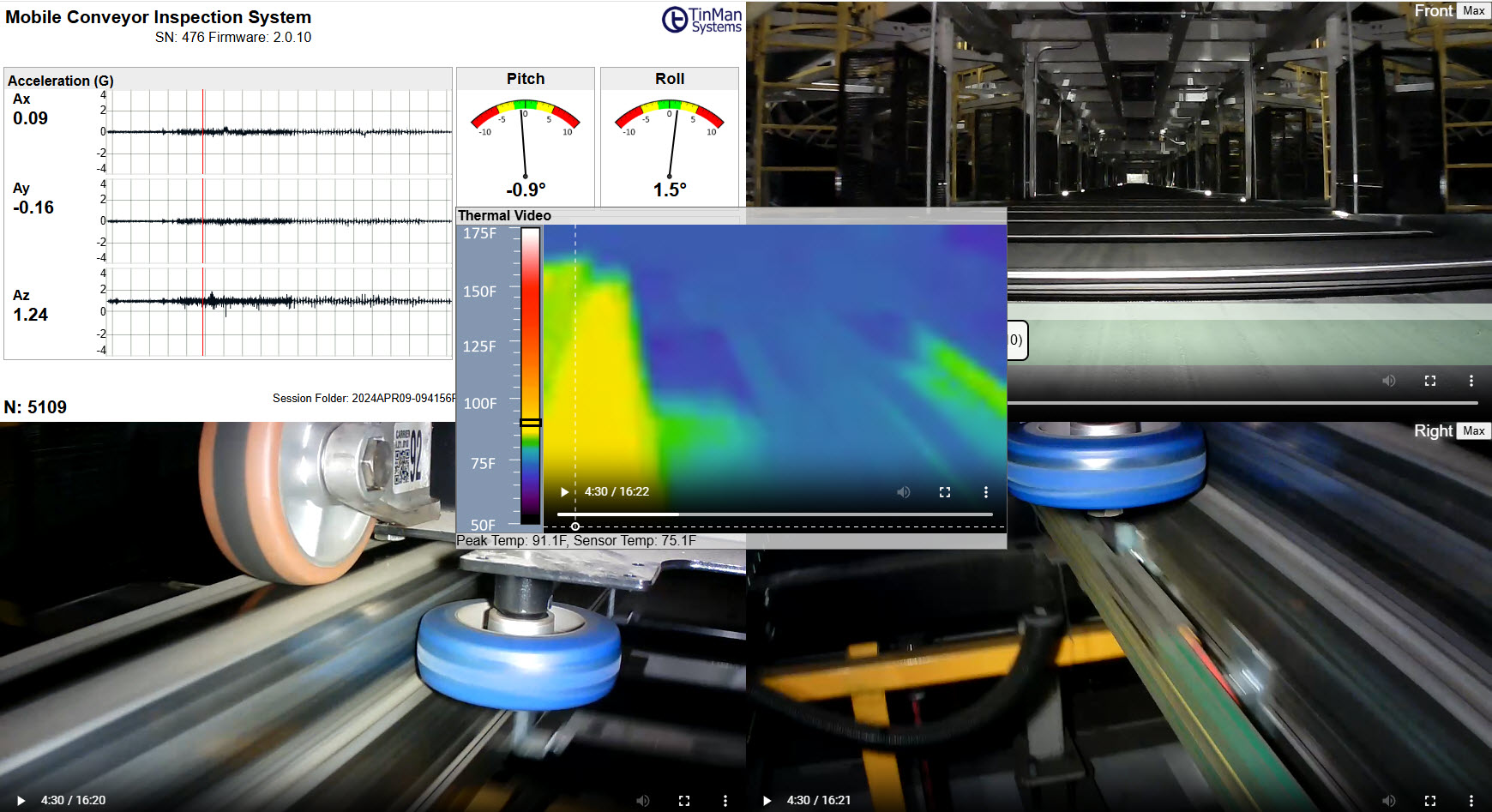

TinMan Systems provides continuous and mobile visibility across long conveyor lines—revealing alignment drift, bearing wear, thermal hotspots, and vibration signatures that impact flow. Operators gain a clear, real-time view of mechanical health across the entire network.

Explore Conveyors →

Sorters

High-speed sorters operate at the edge of mechanical capacity. SORTERVision™ captures synchronized video and multi-sensor data from inside the sorter during live operation—providing component-level insight into wheels, brushes, belts, and motors.

Explore Sorters →

Baggage Handling

TinMan Systems enhances reliability across EDS lines, make-up carousels, and high-throughput baggage conveyors. By detecting mechanical drift early, airports reduce delays, maintain passenger flow, and improve operational resilience.

Explore Baggage Handling →The Common Thread

Across conveyors, sorters, and baggage systems, the challenge is the same: thousands of moving parts operating at high speed. Even small deviations—heat buildup, vibration changes, alignment drift—can cascade into jams or full system stoppages.

TinMan Systems brings real-time clarity to these environments, giving reliability teams the insight they need to maintain throughput and prevent failures before they occur.

See Inside Your Conveyor Systems

TinMan’s Cascades and MCIS systems give operators a clear, end‑to‑end view of conveyor performance—validating maintenance work, confirming repairs, and revealing issues that static monitoring often misses.

Learn More

Inspect Your Sorters from the Inside

SORTERVision™ provides an inside‑the‑machine perspective—capturing synchronized video and sensor data during live operation. Teams gain the clarity needed to diagnose friction spikes, component wear, and alignment issues before they affect throughput.

Learn More

Improve Airport Baggage Reliability

TinMan Systems enhances visibility across EDS lines and make‑up carousels—helping airports maintain flow, reduce delays, and ensure consistent performance during peak demand.

Learn More

System Solutions

All powered by the TinMan real-time platform.

Cascades System

Cascades delivers continuous, wireless multi-sensor monitoring for conveyors and sorters— providing real-time visibility into mechanical behavior across the entire line.

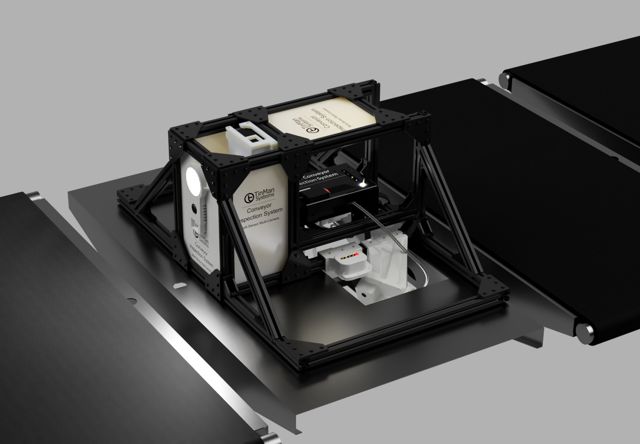

Explore Cascades →MCIS

The Mobile Conveyor Inspection System captures synchronized data across long conveyor runs— offering a mobile, high-resolution view of system performance.

Explore MCIS →SORTERVision™

SORTERVision™ embeds sensors and cameras directly into sorter carriers—providing an inside-the-machine perspective during live operation.

Explore SORTERVision →